Pulleys

A single failed conveyor pulley can bring your entire operation to a standstill. At Osmak, we view pulleys as the core of your system’s reliability. We custom-engineer each one for maximum grip and flawless rotation, ensuring they endure the most demanding industrial environments and protect your operations.

Conveyor Pulleys We Offer

Our conveyor pulleys are built for optimal performance in their intended application. Browse our full selection below to find the right component for your system:

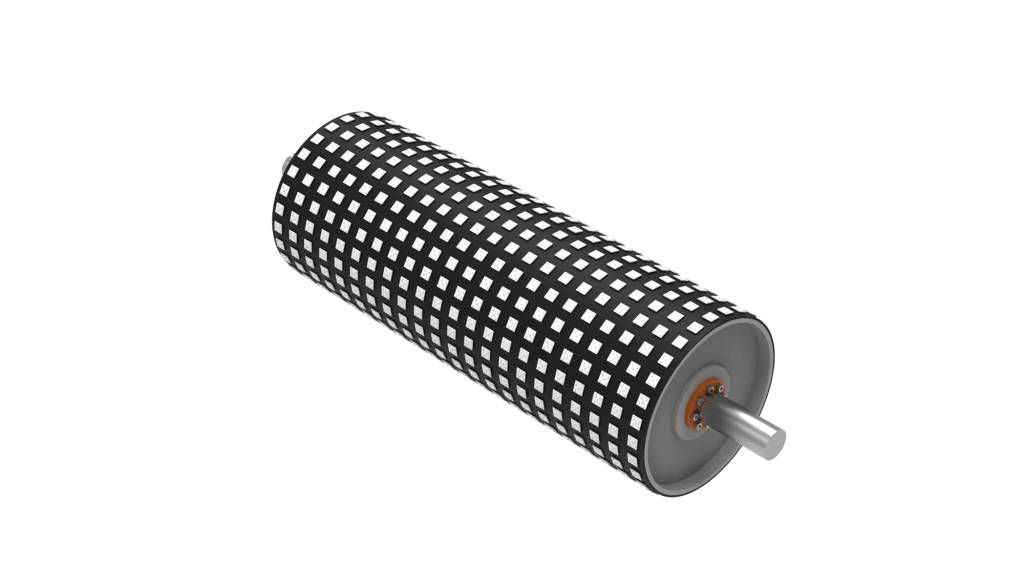

Ceramic Coated Pulley

Ceramic Coated Pulley A ceramic-coated pulley is a type of pulley used in conveyor belt systems, where the surface of the pulley is

More Info

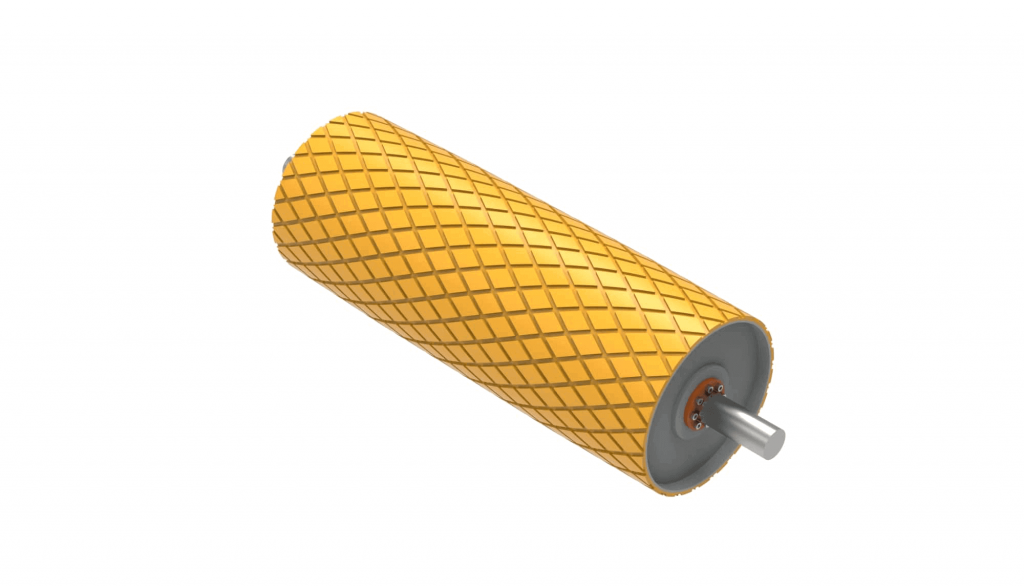

Polyamide Coated Pulley

Polyamide Coated Pulley A polyamide-coated pulley is a type of pulley used in conveyor belt systems, where the surface of the pulley is

More Info

Magnetic Pulley

Magnetic Pulley A magnetic pulley is a component used in conveyor systems, primarily for separating materials. It contains a magnet and is designed

More Info

Snub Pulley

Snub Pulley The snub pulley is a component used in conveyor belt systems, designed to change the direction of the belt or adjust

More Info

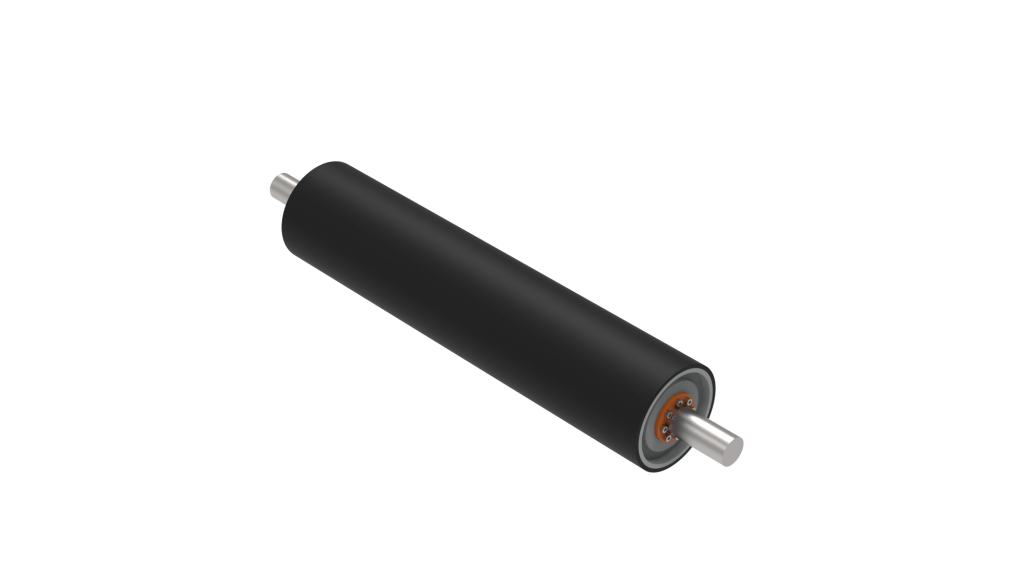

Motorised Pulley

Motorised Pulley A motorized pulley is a conveying solution in which the motor and the pulley are integrated into a single unit within

More Info

Wing Pulley

Wing Pulley The wing pulley is a component used in conveyor belt systems, designed to clean the material remaining on the belt and

More Info

Drive Pulley

Drive Pulley The drive pulley is typically the main component in conveyor belt systems that is driven by the motor and facilitates the

More Info

Tail Pulley

Tail Pulley The tail pulley serves as a critical component in conveyor belt systems. Commonly used in industries such as mining, quarries, and

More Info

Benefits of High-Quality Conveyor Pulleys

A high-performing conveyor pulley system is essential for your business. Choosing the right, precisely engineered pulleys offers real, tangible benefits that directly fuel your operational success.

Maximize Power and Efficiency

Pulleys are the core of the drive system. Utilizing properly sized and lagged pulleys, such as the drive pulley supported by the snub pulley, ensures that the maximum power from the motor is transferred to the belt with minimal slippage. This efficiency boost allows your system to run faster and more reliably, increasing overall production output.

Ensure Belt Longevity and Protection

Your conveyor belt is a major investment, and quality pulleys keep it safe. The right selection dramatically reduces the daily stress and wear that tears belts apart. Pulleys with specialized lagging, such as ceramic-coated pulleys, ensure excellent grip while distributing tension evenly. Innovative designs like the wing pulley actively clean the belt, preventing material buildup that leads to tracking problems and premature belt damage. This protection extends the working life of your most expensive consumable part.

Maintain Precise Belt Tracking

Unwanted belt wandering leads to spillage, component wear, and unexpected downtime. Accurate tracking is achieved through the precise alignment and geometry of your pulleys, especially the tail pulley. By guaranteeing the belt stays on its intended path, you eliminate messy spillage, reduce wear across your entire system, and prevent those frustrating, unscheduled production halts.

Cut Down on Maintenance Costs

Downtime is a direct hit to your profit. Our robust conveyor pulleys are built to endure the continuous, harsh demands of industrial environments. By choosing durable components, like our sealed motorised pulleys, you significantly reduce external parts that fail or require constant servicing. This heavy-duty focus ensures fewer breakdowns, lower labor costs for maintenance, and maximum operational continuity.

Partner with Osmak for Your Custom Pulley Needs

We believe the right component makes all the difference. At Osmak, we thrive on creating pulley solutions that outperform in the toughest industrial environments. Whether your system requires a simple, durable tail pulley or a highly specialized lagging solution, we have the expertise to build the exact component you need to perfect your material flow.

Ready to build a more reliable conveyor system? Contact our team today to discuss your needs for either custom pulley solutions or a complete custom conveyor system.