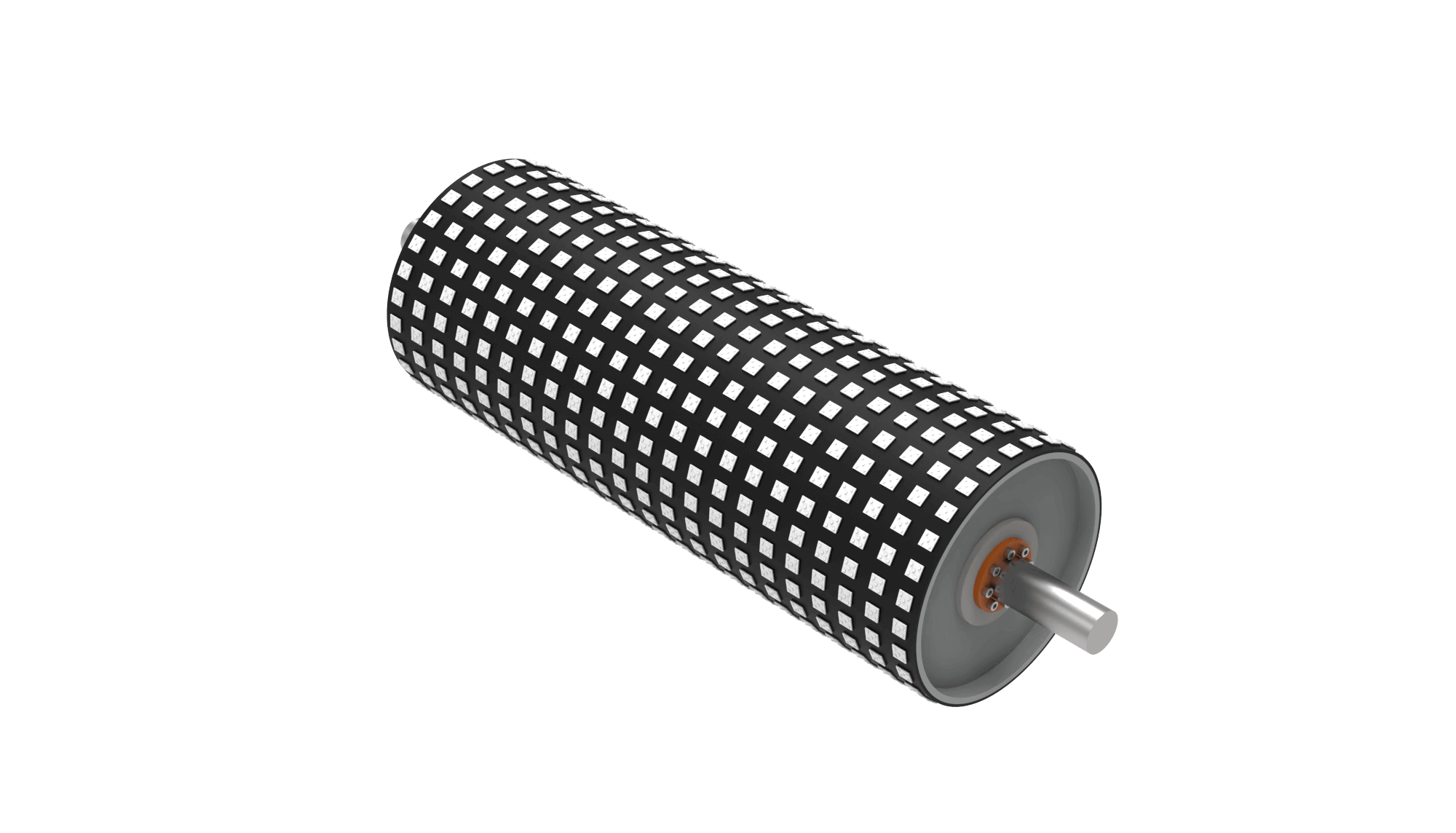

Ceramic Coated Pulley

Ceramic Coated Pulley

A ceramic-coated pulley is a type of pulley used in conveyor belt systems, where the surface of the pulley is coated with ceramic material. This type of pulley is specifically designed to provide durability under harsh operating conditions. The ceramic coating grants the pulley superior wear resistance, high heat resistance, and improved friction properties. Due to these characteristics, ceramic-coated pulleys are commonly used in heavy industrial applications, mining sites, and quarries.

Working Principle of Ceramic-Coated Pulley

The ceramic coating forms a tough and durable layer on the surface of the pulley. This layer increases the coefficient of friction at the points where the pulley contacts the conveyor belt, preventing slippage and minimizing wear on the pulley. Additionally, the ceramic coating provides resistance to heat and chemicals, allowing the pulley to operate smoothly over long periods. The pulley surface is covered with ceramic plates or granules, enhancing the belt's grip, especially in wet, oily, or dusty environments where the risk of slippage is higher.

The ceramic coating forms a tough and durable layer on the surface of the pulley. This layer increases the coefficient of friction at the points where the pulley contacts the conveyor belt, preventing slippage and minimizing wear on the pulley. Additionally, the ceramic coating provides resistance to heat and chemicals, allowing the pulley to operate smoothly over long periods. The pulley surface is covered with ceramic plates or granules, enhancing the belt's grip, especially in wet, oily, or dusty environments where the risk of slippage is higher.

Features of Ceramic-Coated Pulley

- High Wear Resistance: Ceramic is a very hard material, ensuring the pulley maintains its durability even when in contact with abrasive materials.

- High Friction Coefficient: The ceramic coating provides a stronger grip between the pulley and the conveyor belt, preventing slippage.

- Heat and Chemical Resistance: The ceramic coating withstands high temperatures and chemicals, making it reliable in challenging environments.

- Corrosion Resistance: Ceramic is resistant to corrosion caused by moisture and chemicals, prolonging the pulley's lifespan.

- High Mechanical Strength: The ceramic coating allows the pulley to work without wear, even under heavy loads, for extended periods.

Advantages of Ceramic-Coated Pulley

- Long Lifespan: The high wear resistance and durability of the ceramic coating significantly extends the pulley's service life.

- Better Belt Grip: The high friction coefficient ensures a stronger grip between the pulley and the conveyor belt, reducing the risk of slippage.

- Low Maintenance Requirements: The high durability and wear resistance reduce the need for frequent maintenance, thus lowering operating costs.

- Energy Efficiency: The belt's smooth movement over the pulley without slipping enhances system efficiency and reduces energy consumption.

- Reliability in Harsh Conditions: Ceramic-coated pulleys operate reliably in wet, dusty, chemically-aggressive, or high-temperature environments.

Applications of Ceramic-Coated Pulley

- Mining and Quarries: Used to prevent wear in conveyor systems transporting abrasive materials, also minimizing belt slippage in dusty and harsh conditions.

- Cement Factories: Ensures long-lasting pulleys in environments with high temperatures and abrasive materials.

- Power Plants: Provides long life and low maintenance costs in conveyor systems that transport abrasive materials like coal.

- Recycling: Ensures wear-free operation in systems transporting metals, glass, and other hard materials.

- Rubber and Plastic Industry: Prevents slippage in material handling operations requiring high friction.

Ceramic-coated pulleys are ideal for heavy industry applications where durability, wear resistance, and high performance are required. Their high friction coefficient and resistance to heat and chemicals ensure long lifespan while minimizing maintenance costs, making them particularly effective in harsh environments or when transporting abrasive materials.