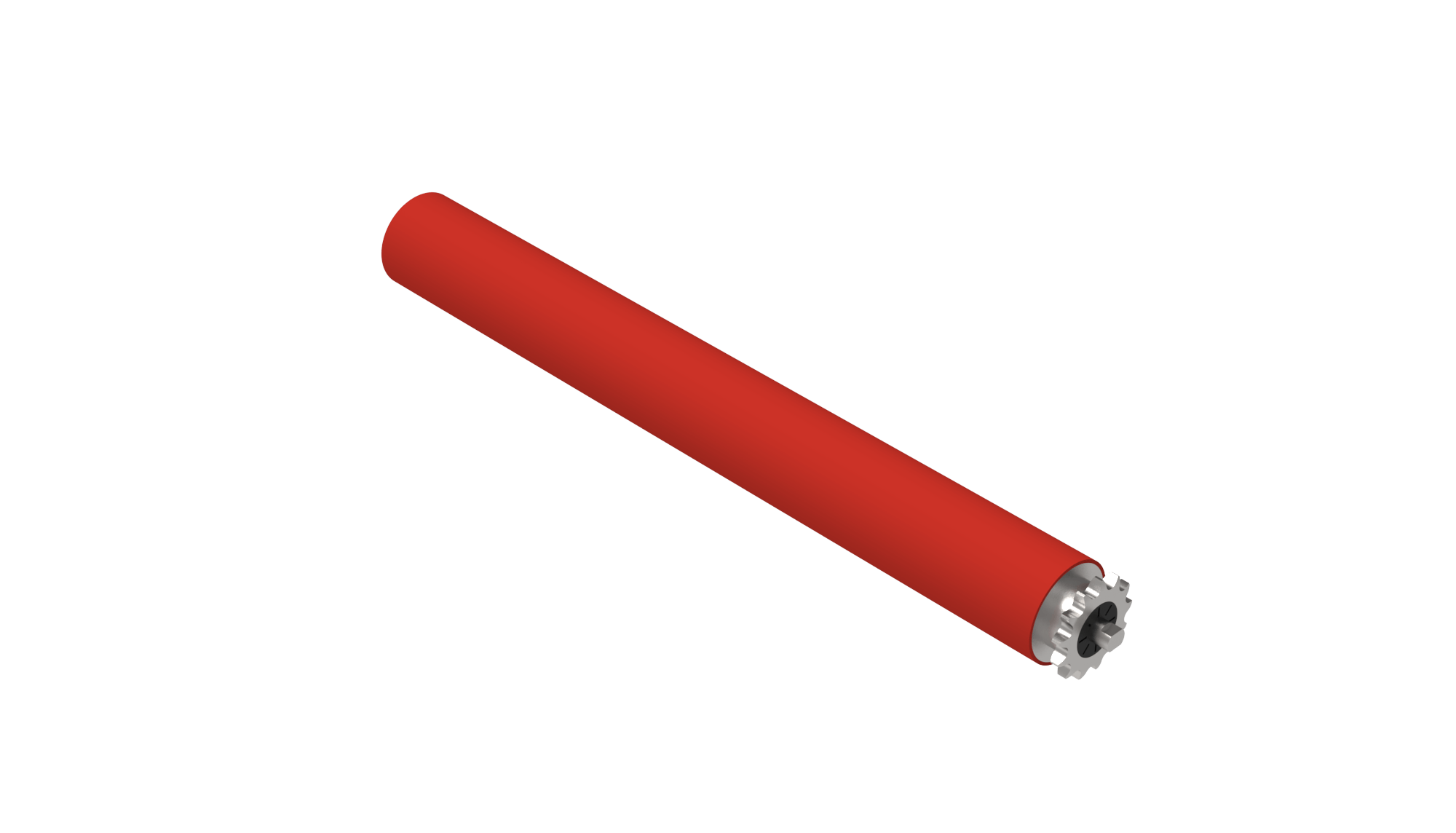

Chain Driven Roller

Chain Driven Roller

A chain driven roller is a component used in conveyor systems that are part of chain-driven transport mechanisms, typically linked to chains. These rollers work in systems powered by chains, transmitting the movement of the chain to ensure the smooth operation of the conveyor belt or transport system. Chain driven rollers assist in securely and efficiently transporting materials, thus contributing to the overall efficiency of the system.

Chain Driven Roles Operating Principle

A chain driven roller is a component used in chain-driven transport systems, operating through the movement of a chain and a gear mechanism. The chain, typically rotated by gears or other mechanisms, rotates the chain driven roller. This rotation helps move materials along the conveyor system. The roller's gear structure aligns with the chain's teeth, enabling the transfer of movement smoothly and continuously.

- Connection to Chain : The chain driven rollers are directly connected to the chain. The chain's motion is transmitted to the roller, which in turn moves the conveyor belt efficiently.

- Gear Mechanism : The gear structure of the roller ensures smooth movement transfer, facilitating the transportation of materials within the conveyor system.

- Rotational Motion : The chain's movement causes the roller to rotate, serving as a key mechanism for guiding the conveyor and materials.

Features

- Durable Materials : These rollers are typically made from high-strength materials such as steel, stainless steel, or other durable metals. This ensures their use in heavy-load environments for long periods.

- High Load Capacity : Chain driven rollers are highly effective in transporting heavy materials, offering a high load capacity.

- Gear Structure : The gear structure ensures compatibility with the chain, efficiently transferring movement.

- Low Maintenance : Due to their durable design, these rollers generally require minimal maintenance, though attention to mechanical wear and lubrication is needed.

Advantages

- Efficient Transport : Chain driven rollers operate in harmony with the chain, ensuring the conveyor system runs efficiently.

- High Power Transmission : With a high load capacity, these rollers ensure safe and efficient movement of heavy materials.

- System Protection : The rollers ensure that the conveyor belt and transport chain function without overloading, contributing to the system's longevity.

- Wide Range of Applications : Chain-driven systems are widely used in various industries, particularly in environments that handle heavy and industrial-grade materials.

Applications

- Mining : In the mining industry, chain driven rollers are used in material transport systems, helping move heavy, hard-to-handle materials.

- Food Industry : Used in packaging and transport within the food sector, these rollers help safely and quickly move products.

- Automotive Industry : Chain-driven systems play a critical role in automotive production lines, ensuring efficient transport of car parts.

- Manufacturing and Assembly Facilities : In production areas such as assembly lines, these rollers simplify the transport of heavy parts.

- Recycling and Waste Management : Chain-driven systems are integral to material handling in recycling plants and waste management operations.

Chain driven rollers are essential components in conveyor and chain transport systems, ensuring the efficient and secure movement of materials. Their gear mechanism, connected to the chain, enables faster and more effective transport. With durable designs, these rollers can be used in heavy-duty environments for extended periods with minimal maintenance. They are widely utilized in industries such as mining, food processing, automotive manufacturing, and recycling.