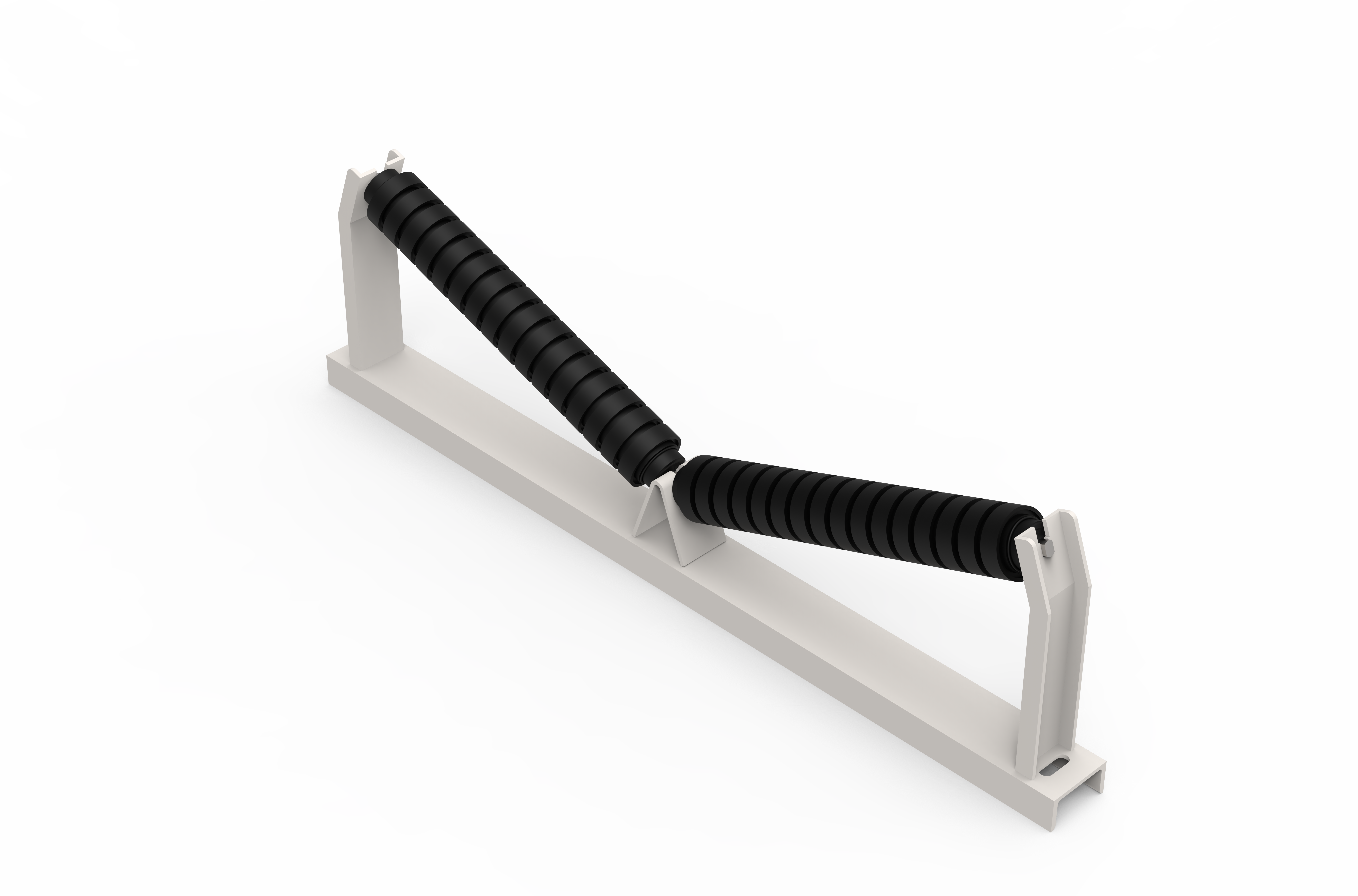

Dual Roller Station

Dual Roller Station

A dual roller station group is a structure used in conveyor systems, consisting of two rollers combined to form a transport station. Compared to single roller station groups, this type offers distinct advantages, particularly for handling more delicate or larger materials. The dual roller setup provides enhanced stability and control, making it ideal for applications where precise and secure material movement is critical.

What is the Purpose of a Dual Roller Station Group?

- Improved Stability: Dual stations provide a wider surface area on the conveyor system, allowing products to move more stably. This is especially beneficial for transporting wide, heavy, or unbalanced loads.

- Guidance and Control: The dual rollers enable better guidance of the transported product or material on the conveyor. The gap between the rollers helps keep the materials in a specific position, preventing slipping or shifting.

- Enhanced Load Capacity: Dual roller stations can carry heavier loads compared to single rollers. The combined support from two rollers provides more stability and makes it possible to transport heavy materials smoothly.

- Suitability for Larger Materials: For transporting materials with larger surface areas, dual rollers provide support on both sides, reducing the risk of bending or slipping and ensuring smooth movement along the conveyor.

Application Areas:

- Heavy Load Transport: Used in warehouses or factories to transport heavy and wide materials such as large metal sheets, wood panels, or big boxes.

- Transport of Delicate Products: Preferred in lines where delicate products need to be transported in a balanced manner, ensuring safe movement without damage.

- Assembly Lines: Ensures more secure and controlled transport of products transitioning through various stages in the production line.

Key Benefits:

- High Load Capacity: Capable of carrying heavy materials.

- Stable Transport: Ensures materials are moved more securely and stably.

- Wide Surface Support: Offers a better transport surface for large and wide materials.

The dual roller station group is ideal for increasing efficiency and safety in production processes, especially for transporting wide, delicate, or heavy loads.