Magnetic Pulley

Magnetic Pulley

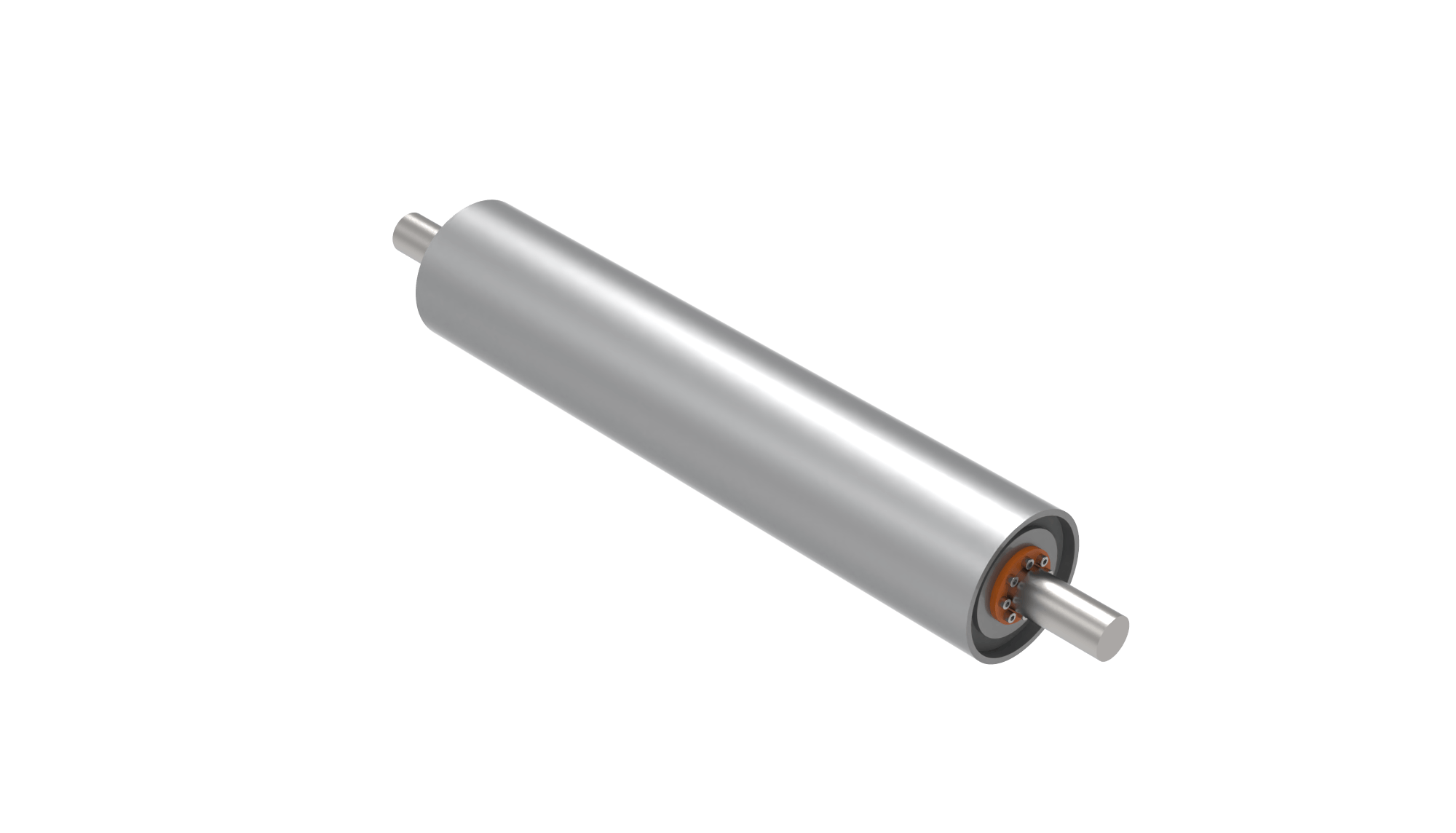

A magnetic pulley is a component used in conveyor systems, primarily for separating materials. It contains a magnet and is designed to separate magnetic metals from other materials. Magnetic pulleys are commonly used in industries such as recycling, mining, and waste management, where they help recover ferrous metals or remove unwanted metals from the system.

Principle of Operation of the Magnetic Pulley

The magnetic pulley is used to extract magnetic metals from materials transported on a conveyor belt. Inside the pulley, there is a powerful magnet. When materials pass over the belt and come into contact with the pulley's surface, the magnet attracts the magnetic metals and adheres them to the pulley surface. Non-magnetic materials continue to pass over the pulley and fall off at a point where the magnetic field weakens as the pulley rotates.

Through this process, metals like iron and steel are easily separated from other materials and can be recycled or removed from the production process.

Features of the Magnetic Pulley

- Strong Magnetic Field : The pulley contains powerful permanent magnets, which pull and separate metals during operation.

- Continuous Operation : Magnetic pulleys work continuously in sync with the conveyor system, ensuring efficient metal separation.

- Different Magnet Strengths : Magnetic pulleys can have different magnetic strengths depending on the type of material being processed and the characteristics of the metals to be separated.

- Low Maintenance Requirements : Due to the minimal number of moving parts and the protected magnets inside the pulley, magnetic pulleys require low maintenance.

Advantages of the Magnetic Pulley

- Metal Recovery : In the recycling industry, it allows for the rapid and efficient separation of ferrous metals (such as steel and iron), making metal recycling more effective.

- Pollution Prevention : By preventing unwanted metal parts from contaminating products or other materials during production, the product quality is improved.

- Energy Efficiency : Magnetic pulleys operate with high efficiency while consuming very little energy, reducing the overall energy consumption of the system.

- High Separation Precision : Thanks to the pulley's magnetic strength, even small metal particles can be separated with great precision.

Applications of the Magnetic Pulley

- Recycling : Used to separate magnetic metals from other materials during the recycling of metal-containing waste.

- Mining : Used to separate and process magnetic minerals in ores.

- Waste Management : Used in the process of separating metal parts for recovery or removal of harmful metals during solid waste processing.

- Food and Pharmaceutical Industries : Magnetic pulleys play a critical role in ensuring product safety by preventing foreign metal parts from contaminating the products.

Magnetic pulleys are an effective solution that increases efficiency in various industrial processes while providing an environmentally friendly way of separating metals. With their ability to rapidly and reliably separate magnetic metals, they are widely used in many sectors, from recycling to production.