Motorised Pulley

Motorised Pulley

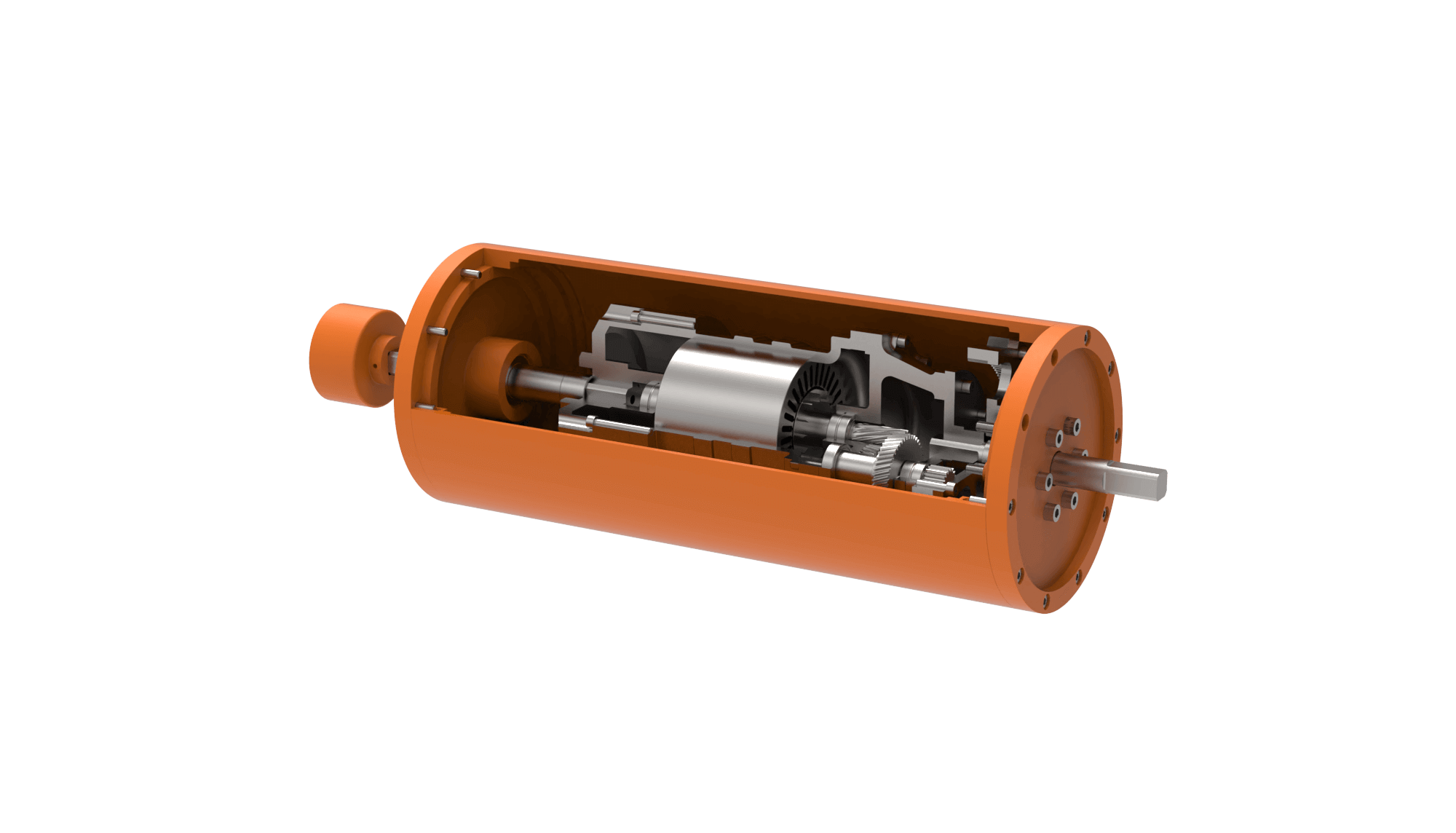

A motorized pulley is a conveying solution in which the motor and the pulley are integrated into a single unit within the conveyor system. Unlike traditional conveyor systems, a motorized pulley does not require an external motor or drive mechanism. Instead, the engine housed within the pulley itself causes the pulley to rotate, which moves the conveyor belt. This compact and integrated design offers advantages, especially in confined spaces and heavy industrial applications.

Motorized Pulley Working Principle

A motorized pulley contains an electric motor inside the pulley itself. This motor generates the rotational motion, which is directly transferred to the conveyor belt. Unlike traditional systems that use external motors and additional drive mechanisms such as chains, belts, or gears, the motorized pulley operates without these components. The engine directly drives the pulley, moving the conveyor belt forward.

A motorized pulley contains an electric motor inside the pulley itself. This motor generates the rotational motion, which is directly transferred to the conveyor belt. Unlike traditional systems that use external motors and additional drive mechanisms such as chains, belts, or gears, the motorized pulley operates without these components. The engine directly drives the pulley, moving the conveyor belt forward.

Motorized Pulley Features

- Compact Design : Since the motor is integrated within the pulley housing, there is no need for external motors or drive components. This saves space and offers a more compact design.

- Reduced Maintenance Requirements : Because there are no wear-prone parts like belts or chains, maintenance needs are lower. Additionally, the engine inside the pulley is protected from external elements like dust and moisture.

- Energy Efficiency : Fewer mechanical components reduce energy losses, making the system more efficient.

- Safer Operation : With all moving parts housed within the pulley, there are no external moving parts, improving safety.

Advantages of Motorized Pulley

- High Efficiency : The integrated motor structure improves energy efficiency in conveyor belt systems. With mechanical losses, power transmission is less effective.

- Space Saving : The absence of external motors makes motorized pulleys ideal for use in confined spaces. They are especially useful in applications with limited space.

- Easy Installation : The installation of motorized pulleys is straightforward as they come as a single unit, without the need for motor connections, belts, or chains.

- Less Wear : Since the engine is enclosed, it is protected from environmental factors like dust, dirt, water, and moisture, resulting in a longer lifespan for both the pulley and the engine.

Motorized Pulley Applications

- Food Industry : In food production lines where hygiene is critical, motorized pulleys offer an ideal solution due to their enclosed design.

- Packaging and Distribution: Motorized pulleys are frequently used in packaging lines where fast and efficient transport is required.

- Mining and Heavy Industry: In harsh working environments with dust, moisture, and heavy loads, motorized pulleys provide structural strength and durability.

- Logistics and Storage: Motorized pulleys optimize logistics processes by improving efficiency in material handling and loading systems.

Motorized pulleys offer a more flexible and practical alternative compared to traditional solutions, providing high efficiency, low maintenance, and a compact structure in modern conveyor systems.