Non-Grip Roller

Non-Grip Roller

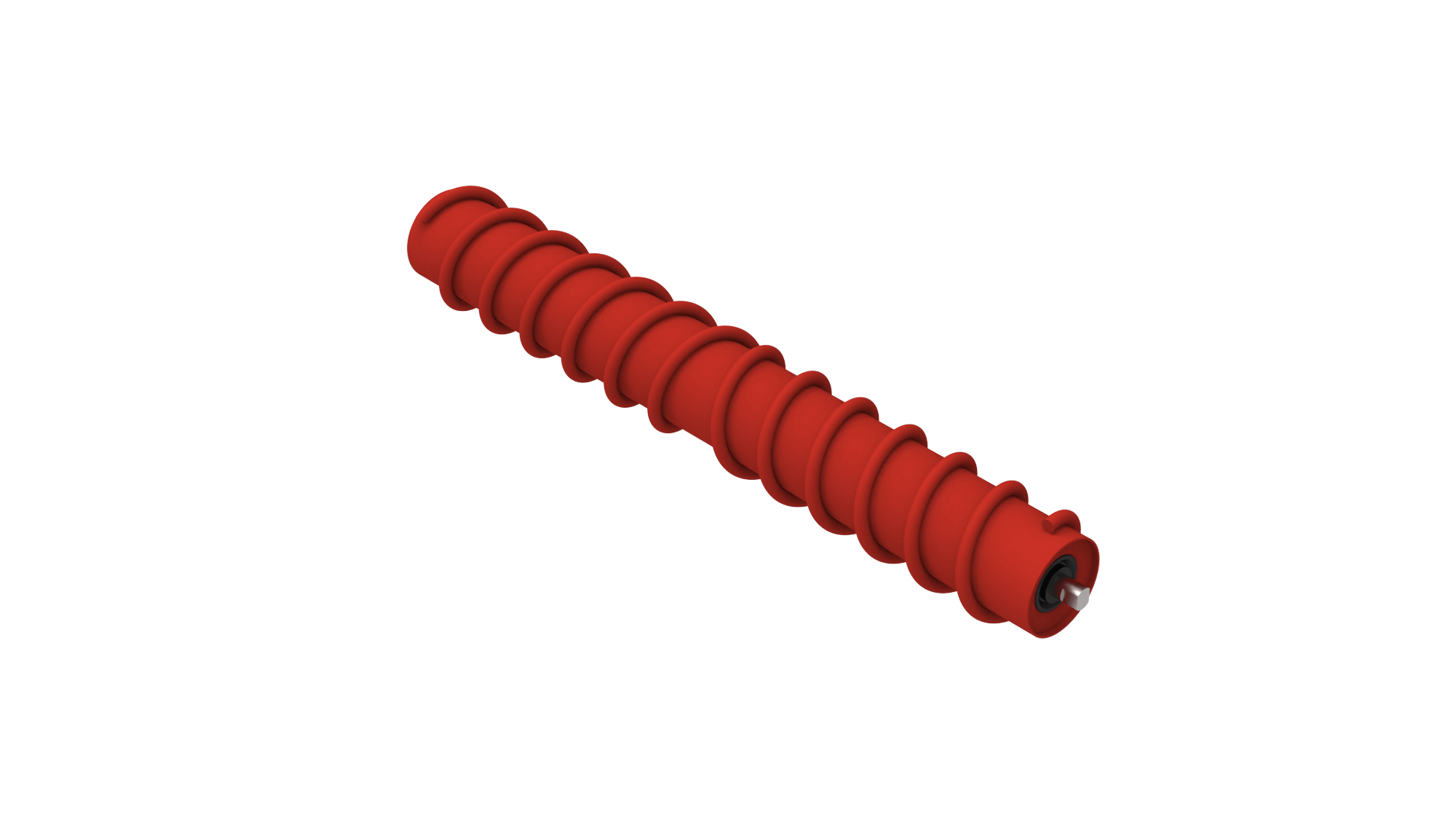

A Non-Grip Roller, typically used in conveyor systems and industrial transportation, is a roller with a helical (screw-like) design. These rollers not only aid in transporting materials but also help guide them from one direction to another due to their specialized design. Non-grip rollers are particularly useful in applications where materials need to be transported on an inclined or spiral plane.

Working Principle of Non-Grip Rollers

A non-grip roller, shaped like a spiral, functions similarly to a screw, guiding materials in a fixed direction. It is typically used in conveyor systems to transport materials, ensuring they move in an orderly and controlled manner. The spiral structure of the roller allows materials to move forward without slipping or dispersing in different directions.

A non-grip roller, shaped like a spiral, functions similarly to a screw, guiding materials in a fixed direction. It is typically used in conveyor systems to transport materials, ensuring they move in an orderly and controlled manner. The spiral structure of the roller allows materials to move forward without slipping or dispersing in different directions.

- Rotating Motion : Non-grip rollers move materials upward or downward as they rotate. This motion ensures the materials move smoothly without slipping, making the transportation process easier.

- Inclined Transport : Non-grip rollers are used in inclined transport applications, allowing materials to move along a sloped path instead of a flat surface. This feature helps save space and facilitates easier transport.

- Spiral Structure : The spiral design of non-grip rollers ensures that materials move regularly and transport is smooth and controlled.

Features

- Spiral Design : The key feature of non-grip rollers is their screw-like or spiral structure. This design ensures materials move steadily and without slipping.

- Durable Construction : Non-grip rollers are typically made of durable materials such as steel, stainless steel, or plastic, which increases their lifespan and ability to handle heavy loads.

- High Load Capacity: Non-grip rollers are suitable for transporting heavy and large materials, with a high capacity for load-bearing.

- Inclined Transport: Ideal for transporting materials on sloped surfaces, non-grip rollers prevent slipping during inclined transport.

- Low Friction: Non-grip rollers reduce friction by maintaining contact with a smooth surface, improving the efficiency of the transport process.

Advantages

- Orderly Transport: Non-grip rollers ensure materials move smoothly and consistently, making the transport process safer and more efficient.

- Inclined Transport Ability: Even on sloped surfaces, non-grip rollers allow for smooth material movement, enabling space-saving transport solutions.

- High Load Capacity: Effective in transporting heavy and large items.

- Long Lifespan: Made from durable materials, they offer long-lasting performance without issues.

- Fast and Efficient Transport: Non-grip rollers enhance the speed and efficiency of the transportation process, improving overall system productivity.

Applications

- Food Industry: Non-grip rollers placed on inclined surfaces ensure the orderly transport of food products.

- Mining: In the mining industry, non-grip rollers make transporting heavy materials more efficient.

- Automotive Industry: Non-grip rollers ensure smooth movement of materials on production lines in the automotive sector.

- Manufacturing and Assembly Plants: Used in assembly lines to move small parts and components.

- Transport and Storage: Used in transport systems and storage areas to ensure the orderly movement of materials.

Non-grip rollers are a special type of roller used in conveyor systems for inclined surfaces or spiral transport operations. Their spiral structure ensures smooth, slip-free movement of materials, making the transport process more efficient. With durable construction, high load capacity, and the ability to handle inclined transport, they are an essential component in industrial transport systems.