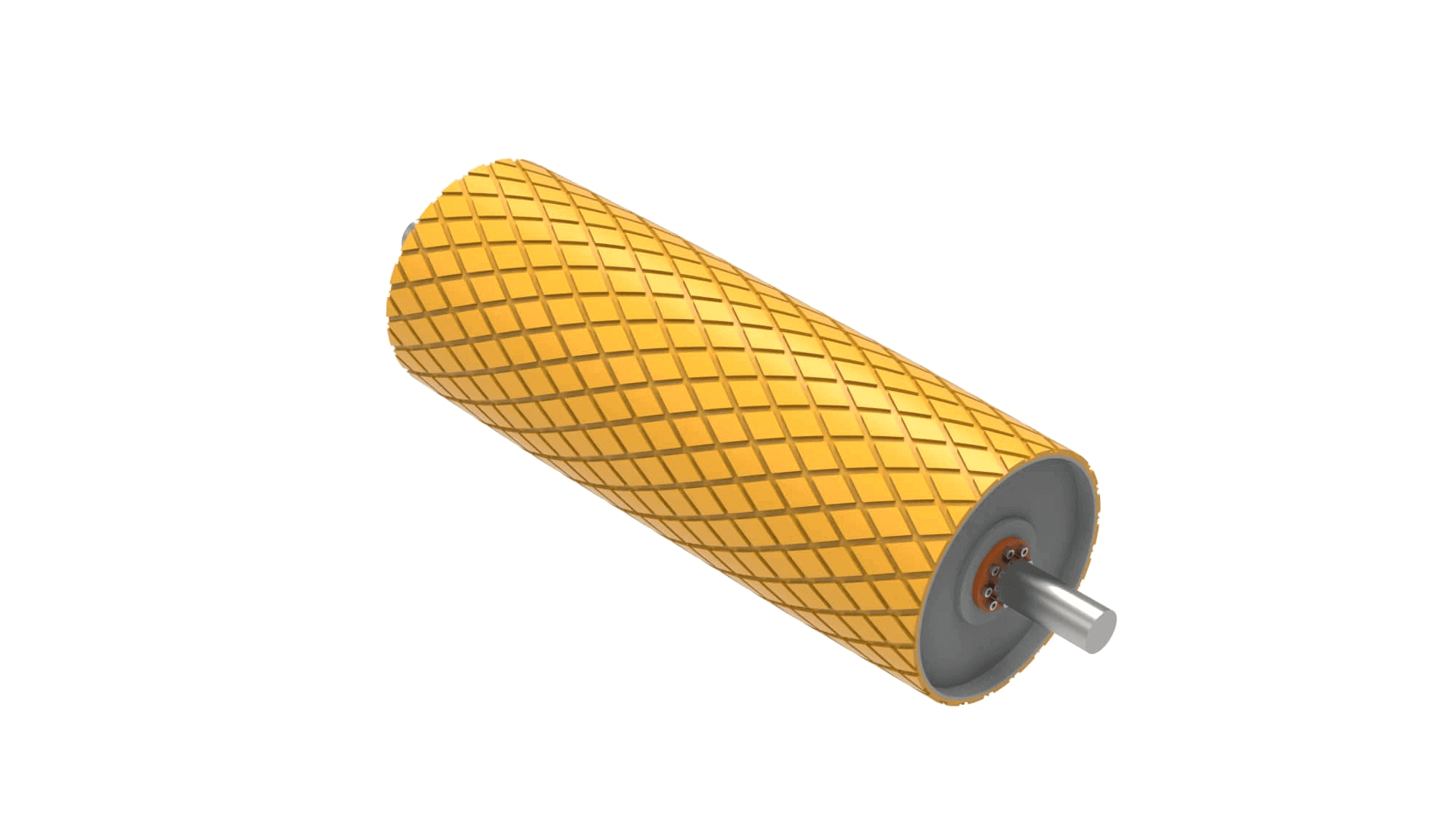

Polyamide Coated Pulley

Polyamide Coated Pulley

A polyamide-coated pulley is a type of pulley used in conveyor belt systems, where the surface of the pulley is coated with polyamide, a high-performance polymer. Polyamide is known for its durability, low friction coefficient, and wear resistance. This coating applied to the pulley surface extends the pulley's service life, reduces maintenance requirements, and enhances the efficiency of the conveyor belt system.

Principle of Operation of the Polyamide-Coated Pulley

The polyamide coating creates a protective layer on the surface of the pulley and reduces friction at the points where the pulley contacts the conveyor belt. This low friction coefficient allows the belt to slide more smoothly, preventing wear on the pulley. Additionally, the polyamide coating protects the pulley from damage caused by materials transported on the belt, thus improving the overall efficiency of the conveyor system. Polyamide-coated pulleys are commonly preferred in conveyor systems that operate at high speeds or transport heavy loads.

Features of the Polyamide-Coated Pulley

- High Wear Resistance : Polyamide is resistant to mechanical wear, which extends the life of the pulley.

- Low Friction Coefficient : It provides low friction between the pulley and the conveyor belt, allowing for easier movement of the belt. This improves the energy efficiency of the system.

- Quiet Operation : The polyamide coating helps the pulley operate more quietly, which is advantageous in environments sensitive to noise.

- Chemical Resistance : The polyamide coating is resistant to oils, chemicals, and other harmful substances. This feature is particularly beneficial for conveyor systems operating in chemical environments.

Advantages of the Polyamide-Coated Pulley

- Long Service Life : The wear and tear-resistant polyamide coating ensures the pulley lasts longer.

- Reduced Maintenance Needs : High durability prevents frequent maintenance, lowering operational costs.

- High Performance : The low friction coefficient and wear resistance allow the pulley and conveyor belt to operate more efficiently.

- Energy Savings : Reduced friction between the pulley and conveyor belt lowers energy consumption and increases system efficiency.

Applications of the Polyamide-Coated Pulley

- Food Industry : In conveyor systems where hygiene is critical, polyamide-coated pulleys are preferred for their easy cleaning and durability.

- Logistics : Ideal for conveyor systems in storage and distribution centers, ensuring efficient material handling.

- Mining : Used in the mining industry, where abrasive materials are transported, polyamide coating protects both the pulley and belt.

- Paper and Packaging Industry : Helps improve efficiency in transporting paper, cardboard, and other packaging materials by ensuring smooth operation of the pulley.

Polyamide-coated pulleys provide a significant technological advancement that enhances the durability and efficiency of conveyor systems. Their resistance to wear and friction makes them a long-lasting, low-maintenance solution. Especially in high-speed or heavy-duty applications, these pulleys ensure the system operates more efficiently, quietly, and reliably.