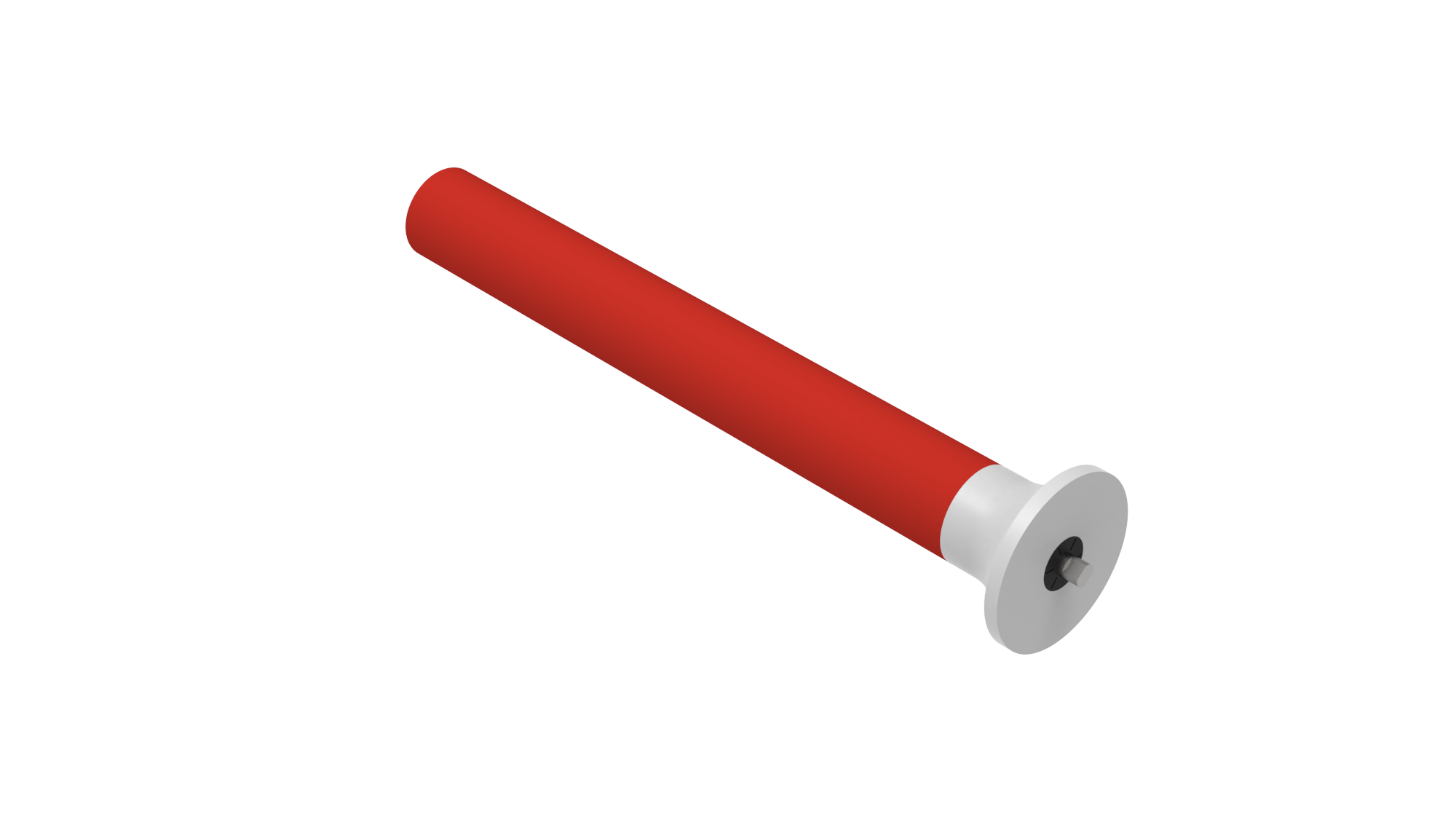

Polyamide Coated Roller

Polyamide Coated Roller

A polyamide-coated roller is a type of roller commonly used in conveyor systems or transportation mechanisms, with a surface coated in polyamide (nylon). Polyamide is a durable, lightweight, and abrasion-resistant plastic material that enhances the longevity of the rollers and allows them to operate effectively in various industrial applications. The polyamide coating increases the roller's resistance to environmental conditions and provides more efficient operation with less friction during transportation.

Polyamide-Coated Roller Working Principle

The polyamide-coated roller is typically used in conveyor systems or transport belt mechanisms. The roller consumes less energy while transporting materials due to its low friction, making the transport process more efficient. The polyamide coating also creates a smooth surface on the rollers, ensuring materials move evenly and without slipping. Additionally, the polyamide coating helps protect the rollers from environmental impacts such as oil, chemicals, and moisture.

The polyamide-coated roller is typically used in conveyor systems or transport belt mechanisms. The roller consumes less energy while transporting materials due to its low friction, making the transport process more efficient. The polyamide coating also creates a smooth surface on the rollers, ensuring materials move evenly and without slipping. Additionally, the polyamide coating helps protect the rollers from environmental impacts such as oil, chemicals, and moisture.

- Low Friction : Polyamide-coated rollers reduce sliding and friction, ensuring more efficient transportation.

- Wear Resistance : The durable polyamide material is resistant to wear, allowing the rollers to be used for extended periods and reducing maintenance needs.

- Chemical Resistance : Polyamide-coated rollers are resistant to certain chemicals, making them advantageous in systems dealing with chemical substances.

- Lightweight : Compared to metal and other coating materials, polyamide is much lighter, facilitating easier transport and assembly of the rollers.

Polyamide-Coated Roller Features

- Durability : Polyamide-coated rollers are highly durable against wear and impact, making them ideal for tough industrial environments.

- Low Friction Coefficient : The polyamide coating minimizes friction during transportation, leading to less energy consumption and reduced heat production.

- Chemical Resistance : Polyamide coatings are resistant to various acidic and alkaline chemicals, making them suitable for chemical plants and factories.

- Versatility Across Industries : These rollers can be used in numerous industries such as food processing, automotive, pharmaceuticals, mining, and recycling.

Advantages of Polyamide-Coated Rollers

- High Durability : Due to their durable structure, polyamide-coated rollers provide long-term use and reduce maintenance costs.

- Efficient Transportation : The low friction properties promote energy savings during transportation and contribute to the overall efficiency of the system.

- Chemical Resistance : Their resistance to chemical substances makes them suitable for use in aggressive environments.

- Lightweight and Easy Installation : The lightweight nature of polyamide simplifies the transport and installation of the rollers.

Polyamide-Coated Roller Applications

- Food Industry : Used for transporting food products safely due to their hygienic and durable properties. Polyamide-coated rollers ensure that food products move without slipping or damage.

- Automotive Industry : In automotive part transportation systems, they offer long-term, efficient use with their durable and lightweight design.

- Chemical and Pharmaceutical Industries : In the transportation of chemicals, polyamide-coated rollers offer safe and efficient transport due to their chemical resistance.

- Mining and Heavy Industry : In environments where heavy loads are transported, the durability and long lifespan of these rollers provide significant advantages.

- Recycling and Waste Management : Used in recycling plants and waste management systems to ensure safe and efficient material transportation.

The polyamide-coated roller is an important component in industrial transport systems due to its durable and wear-resistant structure. Its chemical resistance, low friction properties, and lightweight nature provide efficient and long-lasting transportation processes. These rollers, especially in industries such as food, automotive, chemicals, mining, and recycling, make the transport process safer and more effective.