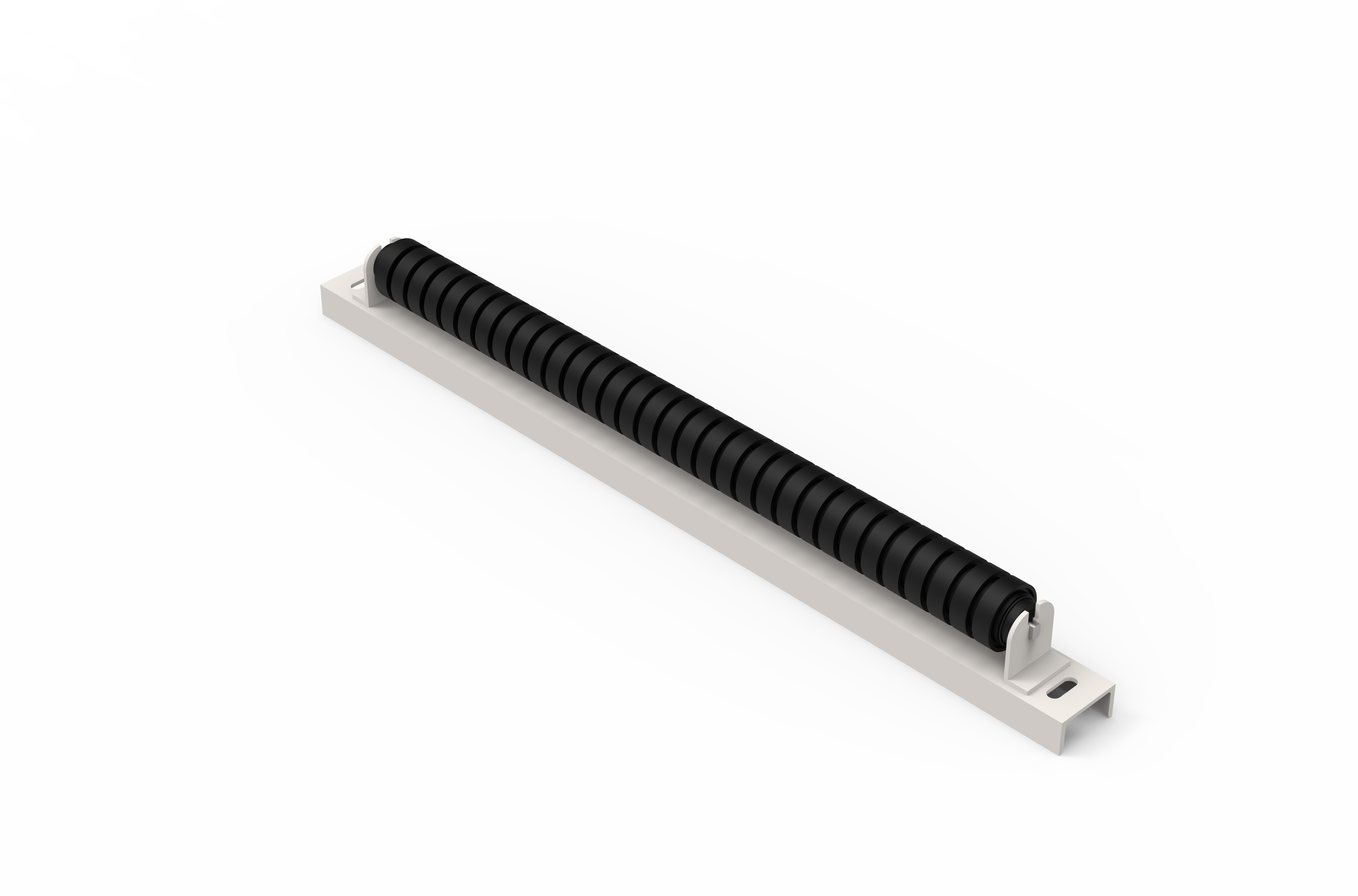

Single Roller Station

Single Roller Station

The single roller station group is a component of a mechanical system used for the transportation and guidance of materials. Roller stations in conveyors ensure that the items being transported move in a smooth and stable manner. These stations typically consist of structures mounted on rollers or cylinders, providing reliable support for the materials as they progress along the conveyor line.

What is the Purpose of a Single Roller Station Group?

- Support and Transport: Single roller stations ensure the smooth movement of materials or products on the conveyor. A single roller station consists of a single roller designed to transport items or materials on a horizontal surface.

- Guidance: The arrangement of rollers helps direct the movement of products in a specific direction along the conveyor line. Single roller stations serve as fundamental structural elements that control and guide this movement.

- Balanced Movement: These stations provide stable and secure transportation, especially for heavy or wide materials, ensuring that they progress smoothly. They prevent excessive sliding or tipping of materials.

- Fast and Efficient Transport: By speeding up material transport in industrial operations, they enhance efficiency in production processes. Single roller station groups offer a simpler and more cost-effective transportation solution.

Application Areas

- Material Handling: Used in factories, warehouses, and logistics centers for transporting heavy loads and large-volume products.

- Packaging Lines: Utilized for quickly transporting products to packaging or shipping stations via conveyors.

- Assembly Lines: Facilitates the movement of products during the assembly or production process on conveyor systems.

The single roller station group is a simple yet effective component that optimizes material transport within a conveyor system.