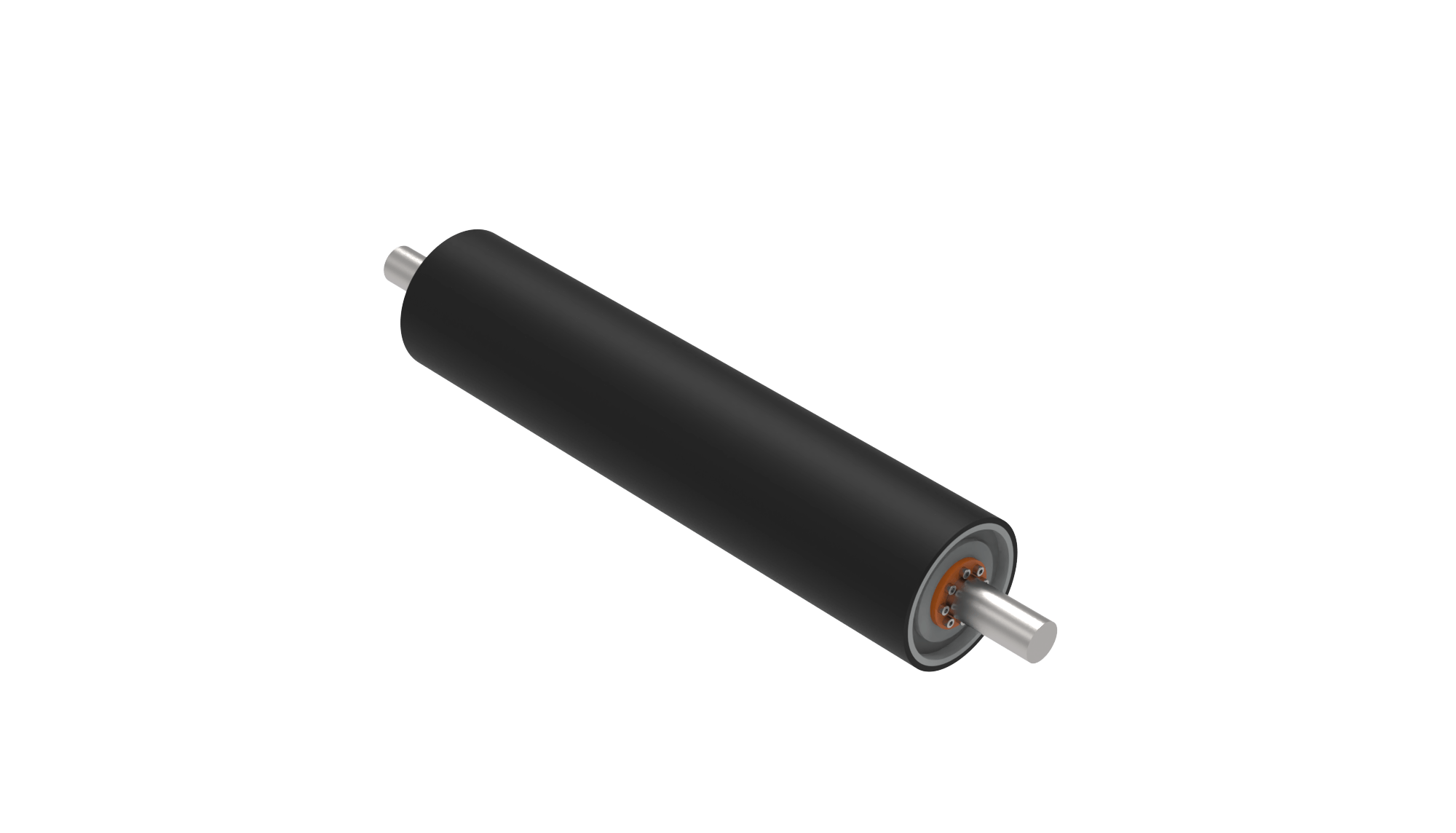

Snub Pulley

Snub Pulley

The snub pulley is a component used in conveyor belt systems, designed to change the direction of the belt or adjust the tension of the conveyor belt. It is typically located at the return section of the system or at points where the belt needs to be redirected at specific angles. Snub pulleys play a critical role in stabilizing the movement of the belt, changing its direction, or ensuring that the conveyor system operates in a specific configuration.

Principle of Operation of the Snub Pulley

Snub pulleys are used to change the path of movement of the conveyor belt. The pulley passes over or under the conveyor belt, redirecting the belt's direction at a specific angle. This pulley is particularly used at corners where the conveyor system needs to change direction or to adjust the belt's tension.

As the belt comes into contact with the surface of the snub pulley, the angle of the pulley changes the direction of the belt. Additionally, the snub pulley ensures the belt moves in a straight line and helps balance the tension in the conveyor system.

Features of the Snub Pulley

- Direction Change : It is used to change the direction of the conveyor belt. Typically, it redirects the belt at angles of 90 degrees or lower.

- Tension Adjustment : Plays a critical role in adjusting the belt's tension. For conveyor belt systems to function properly, the belt must be at the correct tension.

- Friction Reduction : Snub pulleys reduce friction on the belt surface, ensuring smooth movement of the belt.

- Passive Component : It is usually a passive component, meaning it does not involve motorized movement on its own; it only redirects the belt's movement.

Advantages of the Snub Pulley

- Flexible Directioning : Provides a flexible solution for changing the direction of the conveyor belt or adjusting the return movement. This is especially useful in complex and versatile conveyor systems.

- Maintains Belt Alignment : Helps keep the belt steady and aligned, preventing errors and slippage during material transport.

- Extends Lifespan : By maintaining proper tension and direction in the belt system, wear and tear on both the belt and pulleys are minimized, extending the system's lifespan.

- Energy Savings : Ensuring the belt moves smoothly helps the system consume less energy, reducing long-term costs.

Applications of the Snub Pulley

- Mining : Used in conveyor systems at large mining sites or quarries to redirect the belt for transporting materials.

- Industrial Production: Used in conveyor systems on factory assembly lines, especially in areas where the belt needs to be redirected.

- Agriculture: Frequently used in conveyor systems that transport grains or other agricultural products to different areas.

- Logistics and Warehousing: Used in packaging, distribution, and storage systems to move materials in the correct direction and regulate belt tension.

Snub pulleys are an important component that enhances the functionality of conveyor systems. Through their direction and tension adjustment functions, they ensure conveyor belt systems operate more efficiently, smoothly, and consistently.